Our clients in the furniture industry are experts in the design, manufacture and marketing of furniture pieces that are configured, in many cases, with melamine boards. Tables, shelves and cabinets also require other components, from edges to plastic screw covers.

Our equipment and our advanced plastic extrusion technologies are the perfect ally for furniture manufacturers. All our products are designed to make life easier for our customers. We provide the experience and machinery necessary to provide the solutions that companies need.

In the manufacture of furniture you have to think about all the details, with more detailed it is, the more perfect the furniture will be. All our clients look for perfection and customization of a product that ensures the highest quality, from companies in continuous innovation so that together we can create that highest quality product.

Melamine boards are strong, durable and practical solutions. In recent years this material has been used for different uses, making this material a true revolution in the furniture industry. From the most traditional furniture in dining rooms and living rooms to designer kitchens to moisture resistant bathrooms.

But melamine, to achieve visual continuity throughout the piece, requires other elements that give the set the final touch. At Protecnic, we have been color matching boards for more than 25 years and have developed a very extensive range of edges of all kinds, including PVC ABS edgebands sample book., among others.

At Protecnic we have the possibility of adapting to the design that the client needs or adapting to their tastes and being able to choose which tone to go towards or which veto to add to the designs, we are manufacturers, we work side by side with clients to offer the product in which They're thinking.

In the case of plastic screw covers, these are the result of the close collaboration we have with our customers. Their needs, together with our vocation for constant innovation and our extrusion lines, inspire us to develop the tools they need for their work. And screw covers caps are a perfect solution.

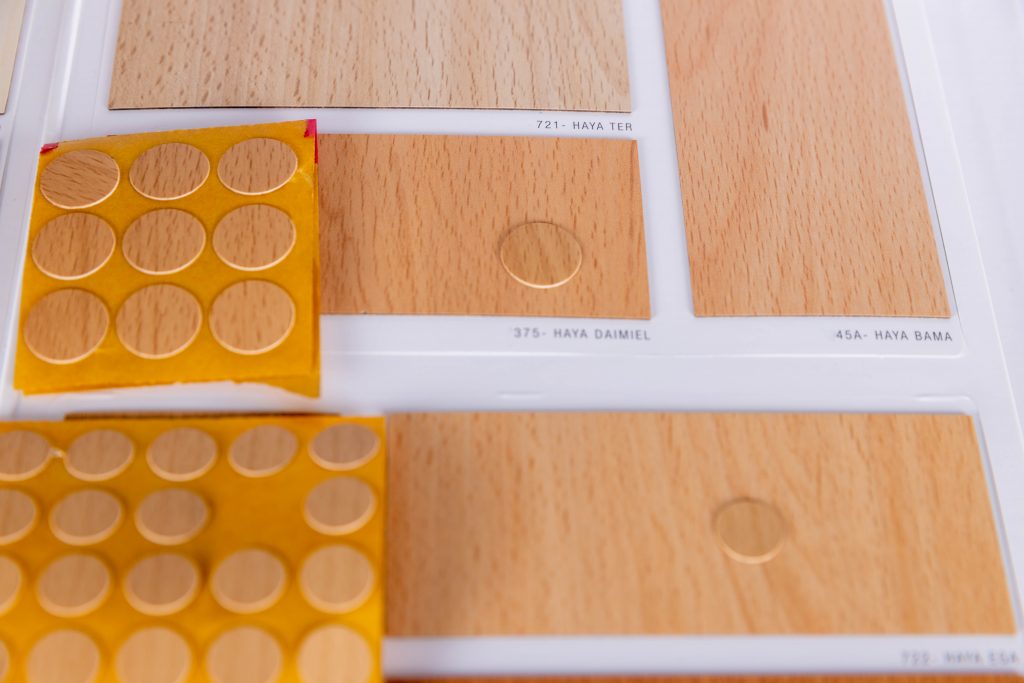

We couldn't leave professionals without the possibility of covering up those small inconveniences of joining parts with screws that reveal those impossible-to-hide tools. Thanks to our plastic screw covers, we can create the illusion of continuity using the same design as in the melamine and the edge.

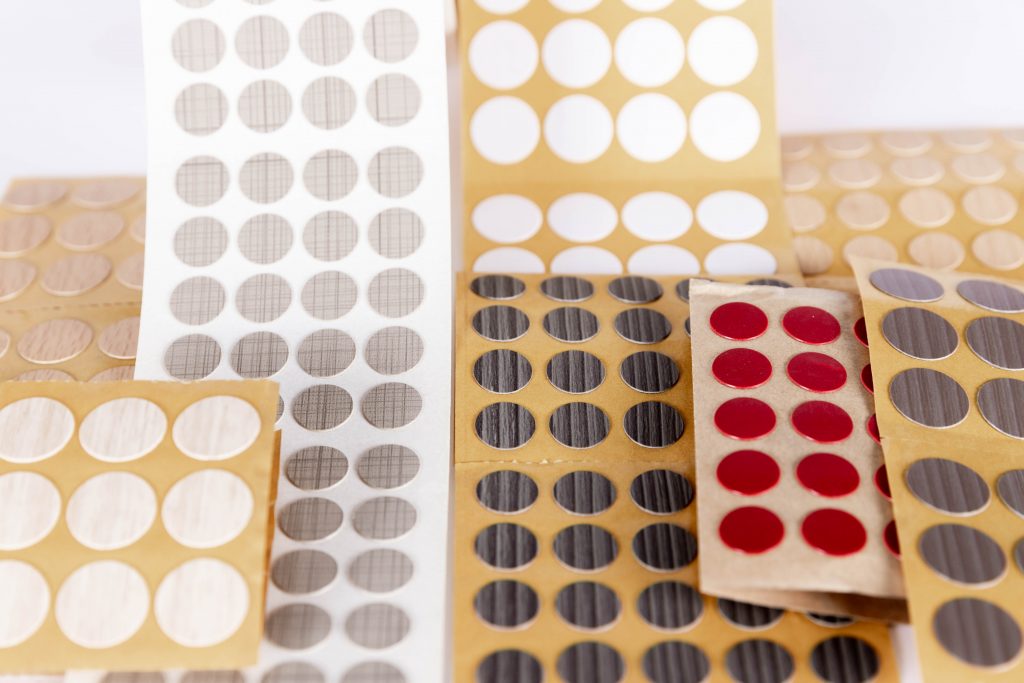

These trims allow the screws of the final piece of furniture to be concealed, thanks to a circular surface that adjusts to its circumference, hiding them from the naked eye. Our sample book, which is continuously growing and already has more than 5,000 references, allows us to adapt our solutions to all types of trends and finishes. No matter the texture, color or design of the melamine, we adapt perfectly to the needs of the client.

The fact that the manufacturing process is similar to that of the edges makes our work simple and that all edge extrusion products have the same aesthetics and quality. Thanks to our experience in plastic extrusion we can achieve an extremely fine edge, but resistant to achieve that effect of continuity so sought after in furniture. The process includes die-cutting the plastic screw covers, so that they are micro-perforated.

Subsequently, the adhesive is applied, so that it is very easy for manufacturers to remove the trims and place them strategically, camouflaging the screws of some pieces that, thus, are perfect in sight. With this mechanism, anyone can use these screw covers, even include them in the cabinet so that the end customer can finish the retouching of the cabinet.