Innovating together

Working together for the best results

Our products

At PROTECNIC we have been developing different products for the furniture industry for more than 25 years, serving to support melamine board manufacturers and the sector as a whole. Discover our own manufactured products

Edgebanding PVC/ABS

Laser Edgebanding

Self-adhesive cover caps

Persiana

Canto flexible

Utillaje

Tambour doors

Profiles and extrusions

T-molding

Edgebands for melamine boards

At PROTECNIC we are industrial specialists in plastic extrusion. Our long history supports us, as well as the precision and customization of all our projects. We have more than 5,000 references of edge designs for melamine boards, which fit millimetrically with the main manufacturers in the market. We constantly innovate and create new designs every week.

Cantos PVC y ABS para tableros de melamina

We have extensive development of designs for the main melamine brands. Find the design you need in our Cross-reference chart or you can contact us with our sales agents.

The edges of PVC (polyvinyl chloride) and ABS (acrylonitrile butadiene styrene) are the sectoral standards at national, European and international level. Its qualities, resistance and ability to adapt to all types of melamine boards make these two types of edges essential for the furniture industry.

Tambour doors

Blinds are another of the products that we can shape at Protecnic for later use in the configuration of cabinets and storage solutions. All our production is concentrated in our three industrial warehouses located in the Castalla Industrial Park (Alicante) that serve orders from 20 countries. These house the Technical Office, the Extrusion Plant and the Strapping Plant.

Plastic extrusion

Our four extrusion lines operate 24 hours a day, six days a week, in three eight-hour shifts. Protecnic's human team and industrial facilities allow us to manufacture 100 million linear meters of edges for melamine boards and adjust each meter of an order to the specific needs, colors, designs and textures required by the client.

T-molding

In recent years the consumption of edges and technical profiles has grown in different sectors and our clients have evolved into increasingly diverse sectors. Advances in panel materials make it possible to use these materials in furniture for all rooms such as kitchens and bathrooms and profiles in uses such as any curved furniture, which needs cushioning and even in the camperization of vehicles. The material used for the manufacture of flexible edge is a special PVC, with different hardnesses, which broadens the range of options, both flexible and semi-rigid, that can be created from our industrial capacity.

Furniture industry – Melamine panel sector

Industrial design and the furniture sector has an ally in our experienced engineering team, responsible for the die-making workshop that, thanks to agile methodologies and advanced machinery, allows us to create custom molds for plastic injection and tools for plastic extrusion. . We advise designers and companies on the tools they need to turn their projects into reality. Some of the industrial design professionals with whom we have collaborated closely are Marcelo Alegre y Javier Cuñado.

Albert of Kassani, a mould and tooling project for plastic injection

Kassani, a Colombian company with over 35 years providing integral solutions to l

Badminton, the icon of industrial furniture design

Badminton, the icon of industrial furniture design and our experience working closely with professionals in industrial design.

TNK Flex, tooling and molds are keys for the project

TNK Flex, tooling and molds key for the project, TNK Flex is an operative and directional chair that adapts

Projects

Meet our customers, they have chosen to work with us for the creation of their spaces. Get inspired by some of our work.

News

At Protecnic we do not stop, we are always innovating and thinking about how to improve our products. In our news section you will find the news of the company.

The Popularity of Industrial Decoration in Modern Design

La decoración industrial, caracterizada por su estética cruda y sin pulir, se ha convertido en una tendencia importante en el diseño moderno de interiores y

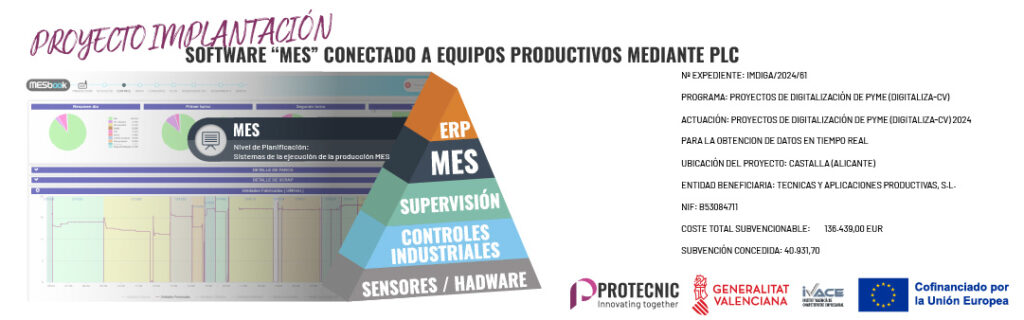

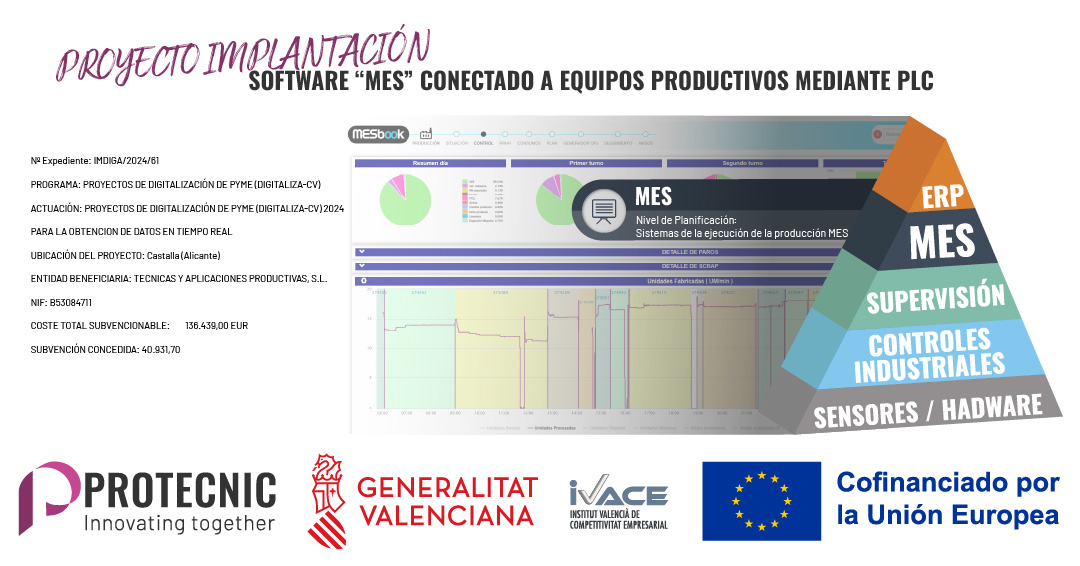

Digitalization Project: Implementation of MES Software at Protecnic

En el marco del programa de ayudas a la digitalización de pymes (DIGITALIZA-CV 2024), Protecnic ha recibido una subvención de 40.931,70 € para la implantación

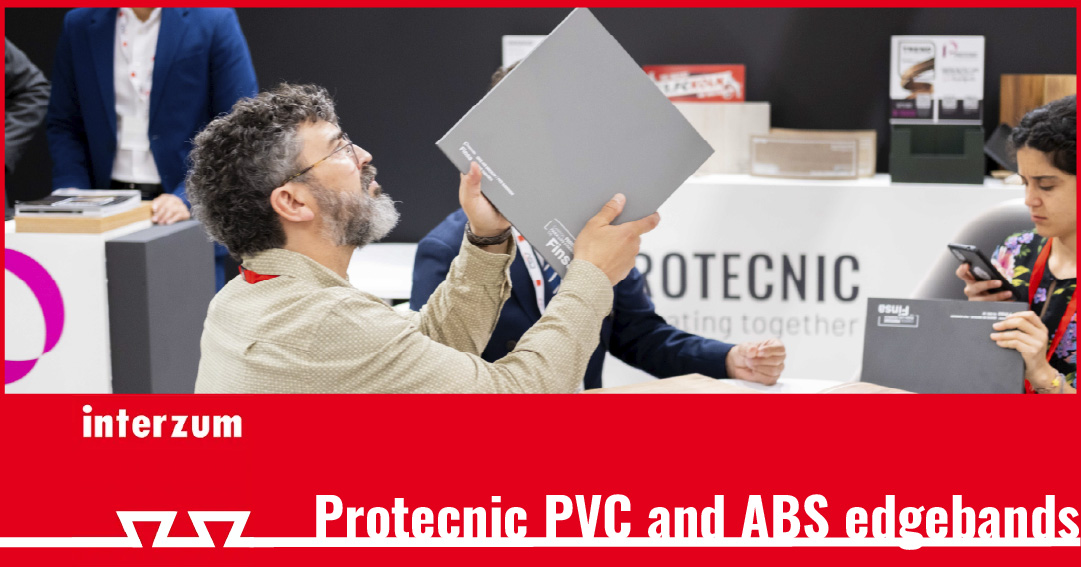

Protecnic at Interzum 2025, a resounding success on the International Stage

Del 20 al 23 de mayo, Protecnic participó activamente en Interzum 2025, una de las ferias internacionales más relevantes del sector del mobiliario y la