When it comes to placing a cabinet in any space, especially if it is in a professional environment, the question always arises of how to make the most of the square meters available, creating an efficient storage solution that is easy to access and does not get in the way of day-to-day activities. Tambour doors for cabinets are very practical for this purpose.

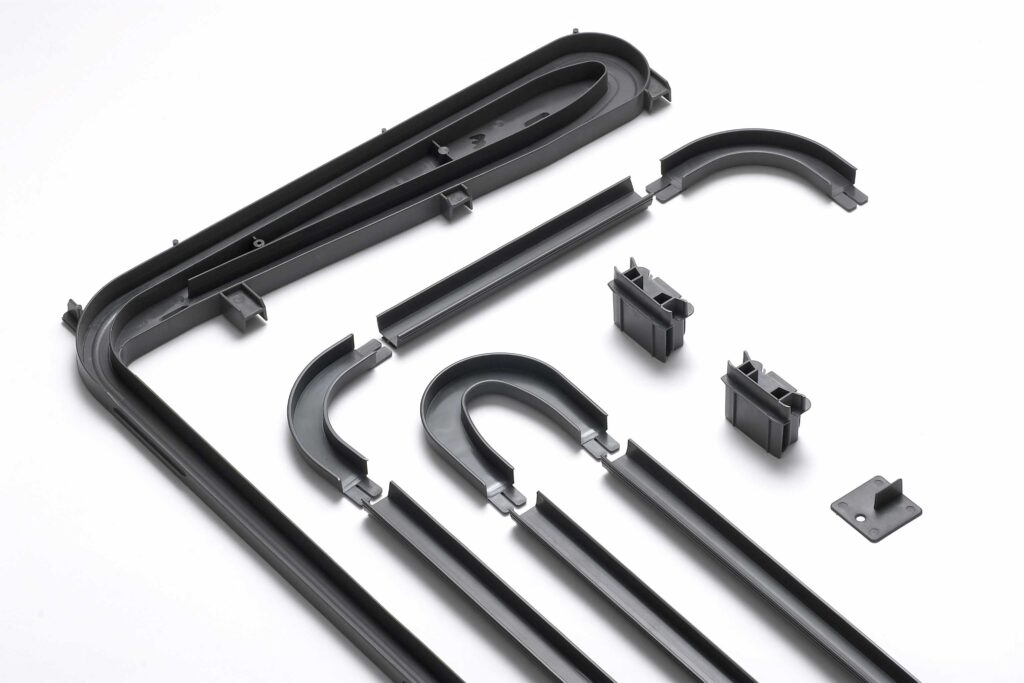

Thanks to this system, the tambour doors made of strong, durable and reliable PVC.This means that the doors do not open forwards or forwards, but are retracted internally towards the rear in a semicircular movement thanks to internal gears.

This allows the cabinet to fit into smaller spaces, as it is not necessary to leave any free space around the cabinet.

What's more, regardless of whether the doors are open or closed, the safety of all the people using the space is guaranteed, eliminating the danger of someone tripping or bumping into the cupboard doors while someone else is searching inside.

This gives it an additional advantage in companies with a high turnover of people or when several members of the same team are storing materials inside the cabinet.

Protecnic has more than 25 years of experience in plastic extrusion technology when it comes to manufacturing tambour doors for cabinets. Our experience with products such as edgeband PVC ABS and special technical profiles gives us the knowledge and know-how we need to create a series of tambour doors for cabinets. With the guaranteed durability of the plastic materials we use in all our industrial processes. We manufacture tambour doors of any size, and they can be decorated to include them in the design required.

In order to meet the continuous flow of orders from our customers in the furniture industry, at our facilities in Castalla (Alicante) we keep four plastic extrusion lines running 24 hours a day, six days a week.

Our four extrusion lines run 24 hours a day, six days a week, in three eight-hour shifts. Constant investment in advanced technologies and a qualified and specialized team are the two key factors that make it possible for us to manufacture 100 million linear meters of edgebanding for melamine boards, among other advanced technical products, every year.