Servicios de Ingeniería para el desarrollo y producción industrial

En PROTECNIC ofrecemos servicios de ingeniería especializados para el desarrollo y la producción industrial. Desde hace más de 30 años trabajamos en matricería profesional, fabricación avanzada, modelado 3D y moldes técnicos orientados al sector del mueble. Nuestro equipo combina diseño industrial, precisión mecánica y un profundo conocimiento en procesos de fabricación, aportando soluciones fiables para transformar una idea en un producto real.

Hoy, nuestra ingeniería sigue siendo el motor de todo lo que hacemos: diseño industrial, prototipado funcional, mecanizado CNC, control dimensional, fabricación interna de moldes y utillajes, extrusión de termoplásticos, inyección de plástico técnico y producción final con criterios de calidad industrial, estabilidad y eficiencia productiva.

¿Qué hacemos?

Ofrecemos servicios de ingeniería industrial con una visión integral del proyecto. Acompañamos a cada cliente en todas las fases del desarrollo. Todo ello con un enfoque orientado a la eficiencia productiva, la repetibilidad y la durabilidad mecánica de cada pieza.

Ingeniería y diseño industrial

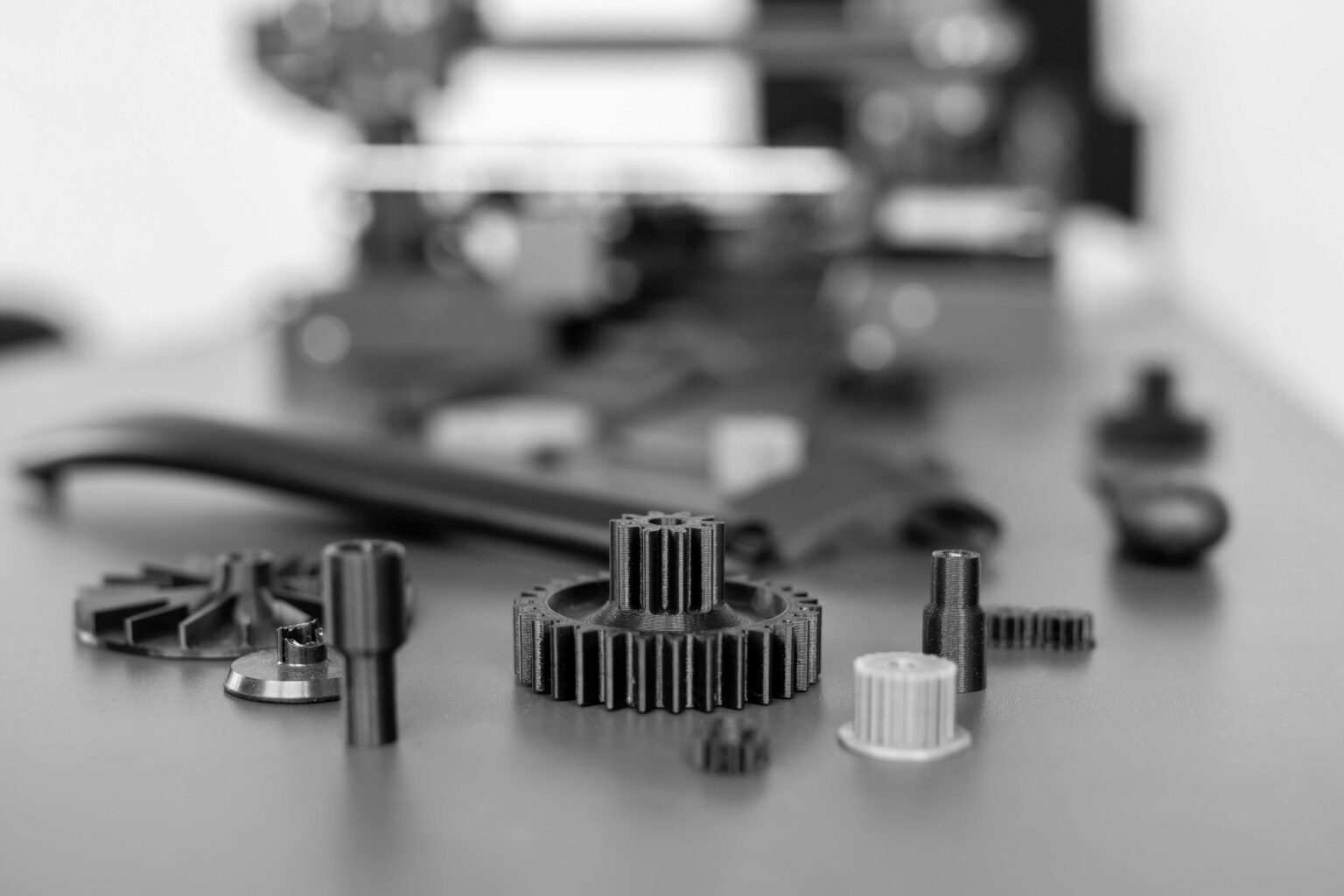

Prototipado funcional y validación

Mecanizado CNC

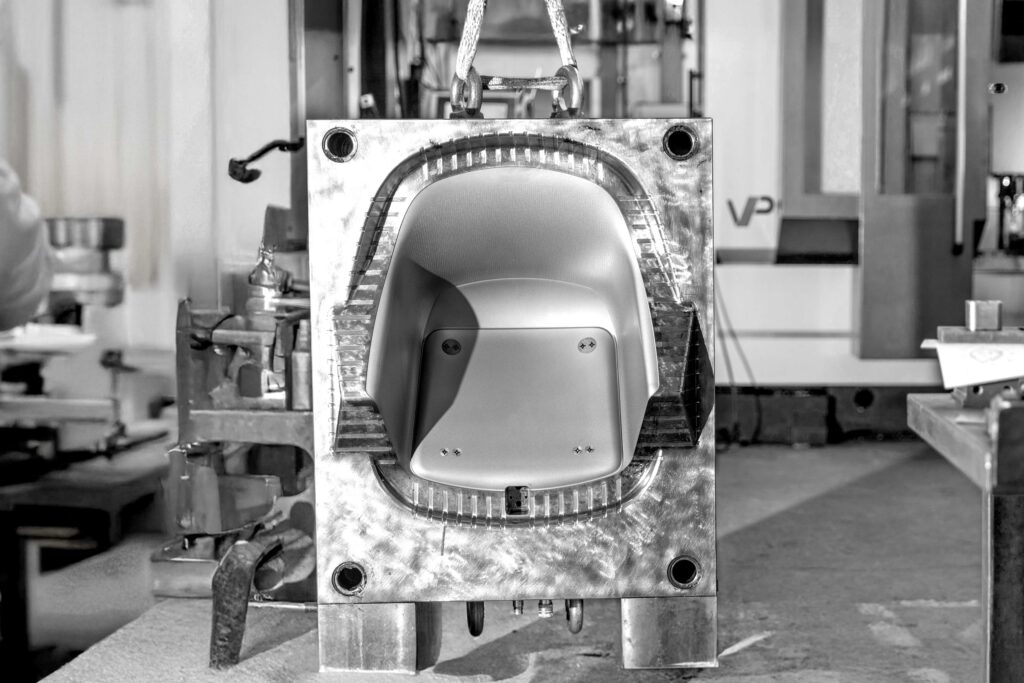

Moldes y utillajes internos

Extrusión (Canto PVC/ABS)

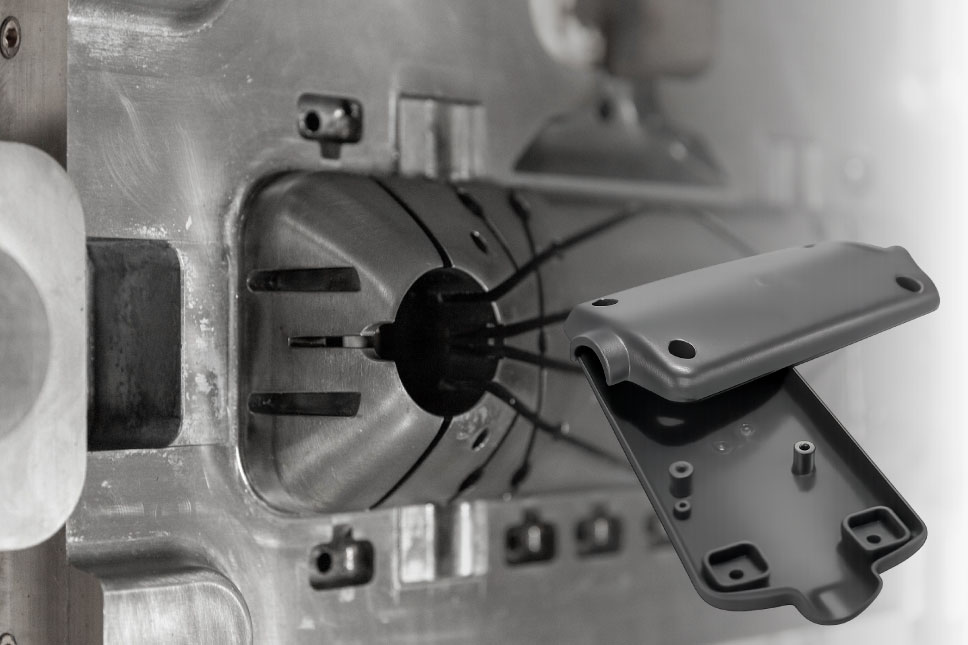

Inyección de piezas técnicas

Aportamos criterio técnico desde la fase conceptual, optimizando geometrías, procesos y materiales.

Transformamos diseños en prototipos reales con precisión, rapidez y capacidad de iteración.

Fabricamos prototipos y piezas técnicas con precisión y rapidez, garantizando estabilidad dimensional y un acabado confiable.

Más de tres décadas diseñando, fabricando y ajustando moldes

para proyectos exigentes.

Expertos en extrusión desde 1996.

Nuestro canto PVC/ABS es una extensión natural de nuestra ingeniería.

Fabricamos piezas con estabilidad dimensional, repetibilidad y calidad industrial garantizada.

- Concepto y asesoramiento técnico

Analizamos la idea inicial, evaluamos materiales termoplásticos, geometrías y tolerancias técnicas para asegurar la viabilidad del proyecto. Nuestro equipo aporta criterio industrial desde el inicio, optimizando procesos y reduciendo costes de fabricación.

- Prototipado y mecanizado CNC

Convertimos los diseños en prototipos funcionales que permiten validar montaje, estética y resistencia mecánica antes de fabricar el molde. El prototipado agiliza la toma de decisiones y mejora la fiabilidad del resultado final.

- Moldes y utillajes

Diseñamos y fabricamos nuestros propios moldes técnicos. La matricería interna garantiza precisión, control dimensional constante y una mejora continua del proceso.

- Extrusión e inyección

Somos especialistas en extrusión de termoplásticos, incluyendo nuestro reconocido canto PVC/ABS, y en inyección de piezas técnicas con estabilidad dimensional y repetibilidad garantizada.

- Piezas finales listas para ensamblaje

Completamos el proceso con inspección, verificación técnica y control de calidad industrial para asegurar productos estables, duraderos y listos para línea de montaje.

¿Por qué Protecnic?

En PROTECNIC somos un partner técnico completo. Nuestra integración de ingeniería de producto, prototipado, matricería, moldes, procesos de fabricación, extrusión, inyección y control integral nos permite aportar:

Precisión y repetibilidad

Trazabilidad completa

Eficiencia productiva

Calidad industrial constante

La modernización de nuestras instalaciones y el refuerzo de nuestros recursos internos nos permiten mostrar la amplitud real de nuestros servicios de ingeniería.

Hoy acompañamos a fabricantes desde la idea inicial hasta la producción final, aportando experiencia en proyectos premiados y un soporte técnico cercano a los departamentos de ingeniería y producto.

Nuestro objetivo es consolidarnos como el partner de referencia en servicios de ingeniería industrial para el sector del mueble y otros sectores que necesiten soluciones técnicas robustas y eficientes.